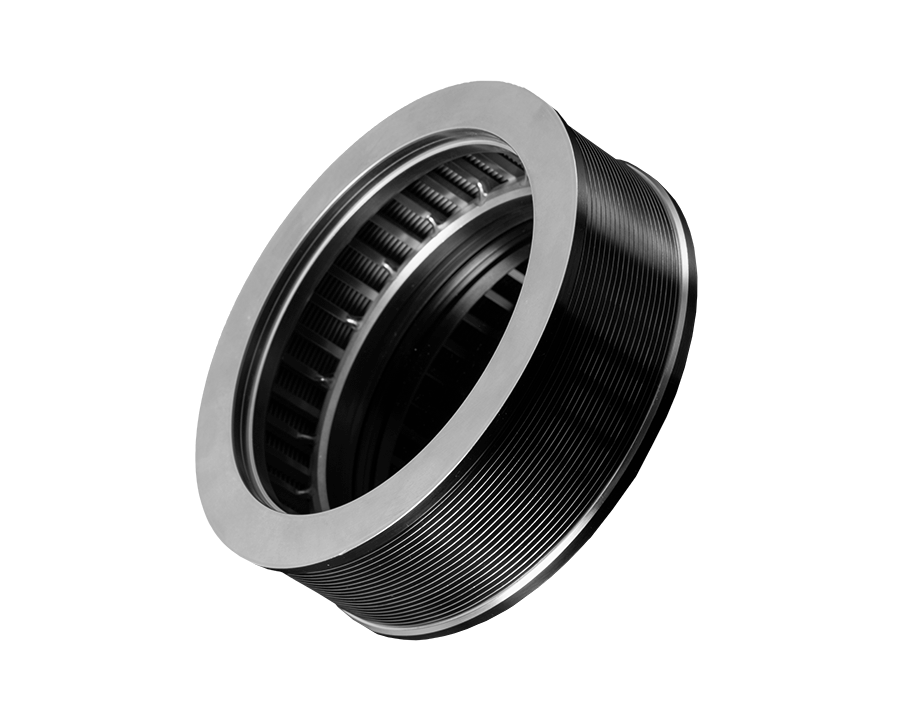

Case

Better chemical filtering for longer thanks to inchromizing

Filtering chemicals causes corrosion and abrasive wear. This prevents proper filtering and dosing, which will soon lead to system failure. Because of the geometries used, regular chrome and nickel surface treatments, are hardly suitable. This restricts the service life to just a few months.

With diffusion-based inchromizing (CM2001), we can greatly improve the existing chemical and corrosion resistance of a chosen stainless-steel base material on the surface. This can increase the hardness to as much as 1100 HV. If high abrasive wear is a problem, then we can increase the surface hardness through hard inchromizing (CM03002) while maintaining corrosion resistance. This boosts the service life of the treated components by more than a year.

Inchromizing makes all ferrous metals ready for long-term use. Heat-resistant, abrasion-resistant, and corrosion-resistant for a longer service life.