Borizing

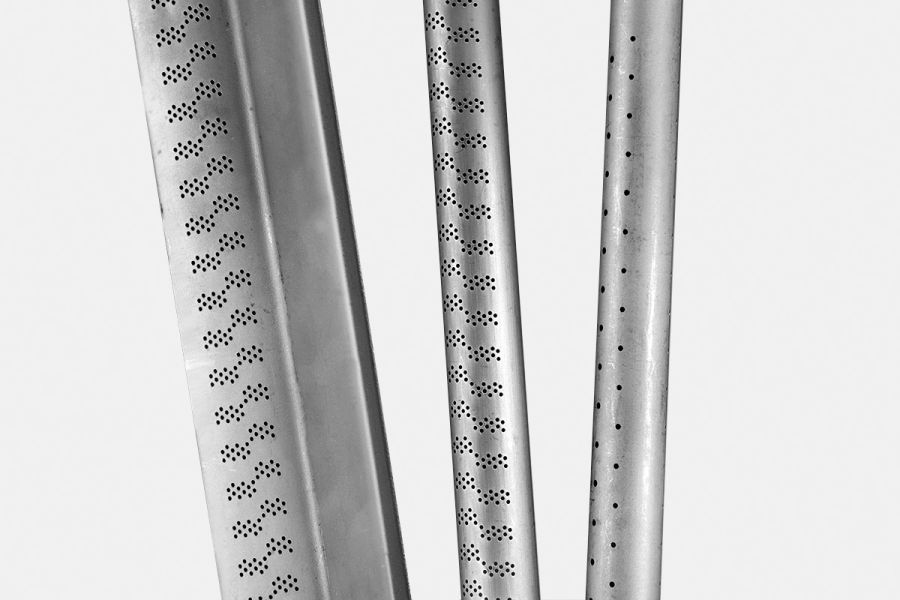

Borizing is a thermal, chemical surface treatment of ferrous metals, which creates a very hard and wear-resistant surface of iron boride. The treatment is highly suited to parts exposed to abrasive or adhesive wear under conditions that don’t require high corrosion resistance.

Characteristics of borizing

- Layer depth 10-300 µm

- Temperature resistance up to 500°C

- Surface hardness of 1600- 2000 Micro-Vickers

- Good adhesion thanks to erratic teeth on the coating

- Core can be refined during and after borizing

- Maximum dimensions 3200 x 2000 x 900 mm

- Other dimensions on request

Cases

For practically any ferrous metal

Any ferrous metal can be borized in principle. But it’s important that the silicon content is no more than 1% and the aluminium content remains below 0.005%. This reduces cold welding (material galling) in the same way as inchromizing does. Borizing provides reasonable corrosion resistance against alkaline and non-oxidizing acids. The treated products are also well protected against cavitation.

Typical applications include gate valves in the chemical industry, screw feeders, rotating spider heads, tools in the glass industry and wear plates

Material analysis

Our work starts with research. From a straightforward material analysis to a more complex damage investigation. At our lab, almost anything is possible.