Inoxeren

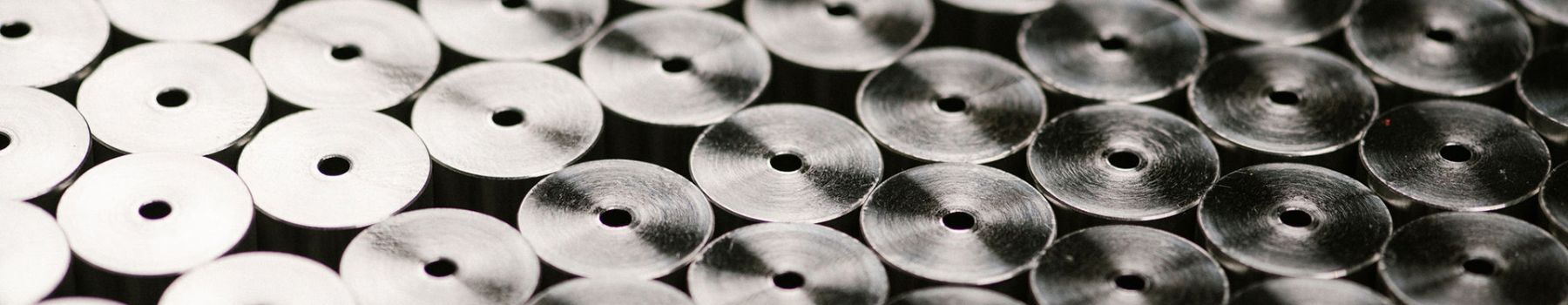

Inoxeren is a unique process for surface hardening of stainless steel, duplex and nickel-based alloys. Under relatively low pressure and temperature, the process significantly improves surface hardness and therefor wear resistance. And all this while maintaining corrosion resistance, size and shape.

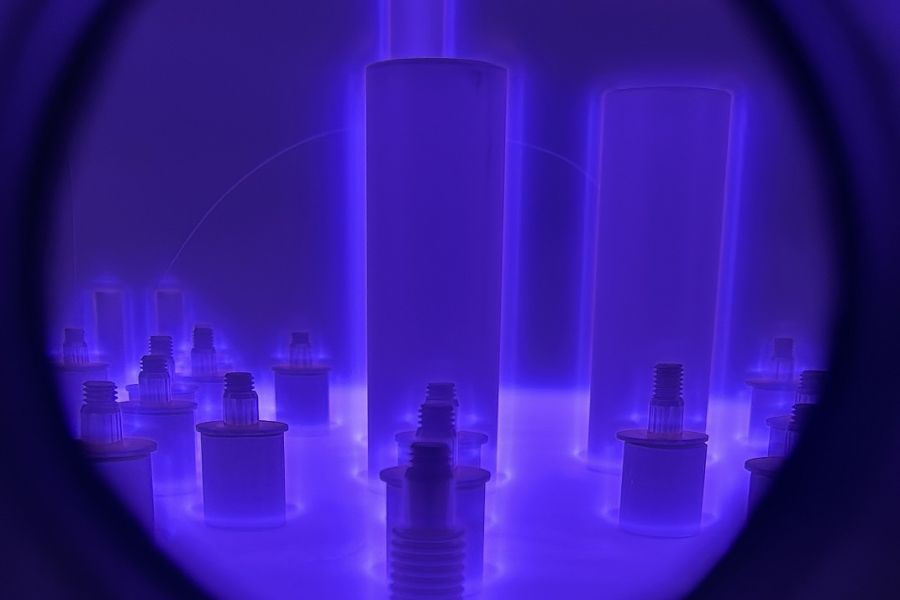

The Inoxeren treatment takes place on the basis of plasma, an ionized gas. This innovative process saturates the surface area of stainless steel grades with carbon and/or nitrogen. This creates a very hard and wear-resistant diffusion zone in the stainless steel surface, with a surface hardness 3 to 5 times higher than the untreated material. Inoxeren is also an environmentally friendly process, without unwanted formation of chromium carbides and/or chromium nitrides.

Locally or fully protected

Inoxeren protects against wear, cavitation and fatigue without altering the corrosion properties of the steel. In addition, stainless steel contributes to the improvement (reduction) of the coefficient of friction and prevents cold welding of material combinations. This also improves the running characteristics of parts.

Due to its unique properties, Inoxeren is very suitable for dimensionally critical parts. Because the size change remains below 3μm, most parts can be manufactured according to the drawing. The possibility of partial treating part of the surface is also special. The range of applications is therefore wide and includes sectors such as mechanical engineering and plant technology, medical technology, fittings, valves, measurement and control components and automotive.

Stainless steel is suitable for most stainless steel grades, including authentic steels (including AISI 304, 1.4301, AISI 316(L) and 1.4404, 1.4571) and duplex steels (including 1.4462 and AISI 318LN). Hardenable stainless steels such as the PH- grades (e.g. 1.4542, PH 17-4, 1.4545 and PH 15-5) are eligible, as are martensitic (e.g. 1.4057 and 1.4122) and ferritic (e.g. 1.4005 and 1.4105) steel.

Characteristics of Inoxeren

- Increase of surface hardness by a factor of 3 to 5

- Diffusion up to approx. 0.15 mm

- Surface hardness: 600-1200 Micro Vickers

- No deformation or size change greater than 3μm

- Higher corrosion resistance, fatigue strength and resistance to wear

- No change in surface roughness

- Preventing cold welding

- Reduction of friction

- Maximum dimensions: Ø 600 x 1000mm

- Maximum load: 750 kg

Material analysis

Our work starts with research. From a straightforward material analysis to a more complex damage investigation. At our lab, almost anything is possible.