Case

Hard inchromizing as a solution to persistent problem

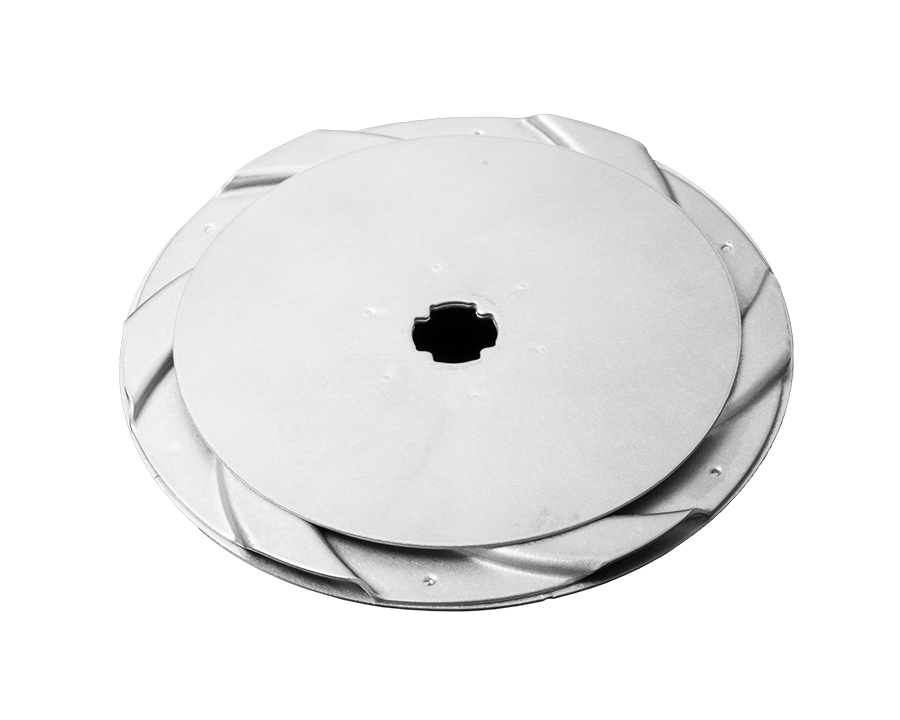

When pumping or dosing lead-free solder, this aggressively degrades materials such as stainless steel. The service life of the pump impellers is often less than one month. Until recently, there was no treatment available to improve this. Alternative materials, such as titanium, are very expensive and difficult to obtain, not to mention difficult to process or weld.

With inchromizing, we give the surface a high chromium content and the high surface hardness that comes with it. As a result, the resistance on the surface increases dramatically, and we can extend the service life to as much as five years.

The best treatment for extremely wear-resistant parts with a hard and dense structure and good running characteristics. Dimensional changes are minimal.